Can Kanban help your organisation? If you’re in the manufacturing space, you know it’s about lean.

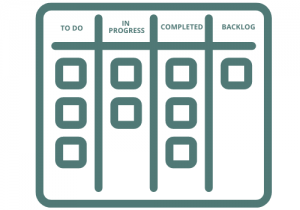

Kanban a method used to manage workflow which provides for greater overall organisation through the definition, management and improvement of processes – aided by a visualisation of inputs, processes and output to maximise efficiency. In this article, we will delve deeper into what it is.

What is Kanban?

Derived from the Japanese word of the same spelling (which means visual board/sign), it was perhaps first used by Toyota as a scheduling system for manufacturing based on customer demand.

The Kanban method itself emerged in the last 15 years, a central theme of it being the minimisation of waste without impact to productivity – creating more value for customers without creating more costs.

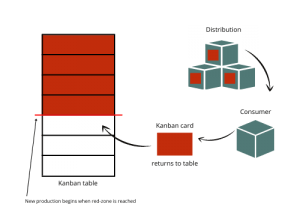

Naturally, it is a ‘pull’ system, responding to demand rather than producing on the basis of prediction. Inventory is created when older inventory gets ‘pulled’ out of stock.

The diagram above aptly shows the ‘pull’ system in action on a Kanban table.

As can be seen, when output is distributed to the consumer, the ‘Kanban card’ returns to the table, with new production beginning when the red zone is reached.

Benefits of Kanban

Kanban benefits are numerous for your manufacturing process, and include:

Flexibility

The Kanban method can be applied to all aspects of your organisation, much further away than the assembly line.

From manufacturing to marketing, a kanban table can be physically or virtually represented and utilised for workflow improvement and leaner processes.

Improved Processes

A key principle of lean and Kanban is the continuous improvement of processes.

The visualisation of processes through Kanban makes it so much easier to review them to improve where necessary, maximising efficiency, reducing costs and cutting waste.

Better Output

Another core principle of Kanban involves limiting just how much work is in Work In Progress (WIP) at any given time.

This reduces multitasking and entices team members to more closely collaborate towards a shared goal for completion.

Team Morale

The kanban systematic philosophy transcends the process itself and views your assembly team as its own system.

By working as one system, team members are empowered by shared responsibility for a common goal.

Reduce Waste

With this method, component parts are only delivered on the basis of demand, meaning that your storage will have less inventory to have to store.

The pull system means that no product is actually wasted, saving cost and reducing waste.

Better Product

As there is a greater focus on continuous improvement and agile responsiveness, product tends to be of better quality.

The pull system facilitates greater quality control, with less focus on quantity, meaning that errors are much less likely.

Quantum 3’s Kanban Solutions

Quantum 3’s installed solutions allow you to physically implement the Kanban production method within your organisation.

Our storage system solutions allow you to ensure that your stock room, workshop or warehouse runs as efficiently as possible and that your operatives are always working at an optimum height.

These systems allow you to ensure a continuous product flow, thus reducing manufacturing times within a production line environment.

Wit a roller system for product to be loaded from one area and fed directly to the operator, products yet to be worked are queued directly behind one another.

When it comes to storing your goods, our packing systems are the perfect solution for quick and easy access. This can help you keep track of your goods, supplies and parts, giving easy access and improved efficiency.

If static is an issue, we can offer rollers which have an electro static discharge feature and also the frame will be grounded to prevent any build-up of static on the frame.

Read more about our storage systems here. Follow us on LinkedIn to keep up with the latest updates.

To discuss your design and installation requirements, contact us today or visit our shop to browse components.